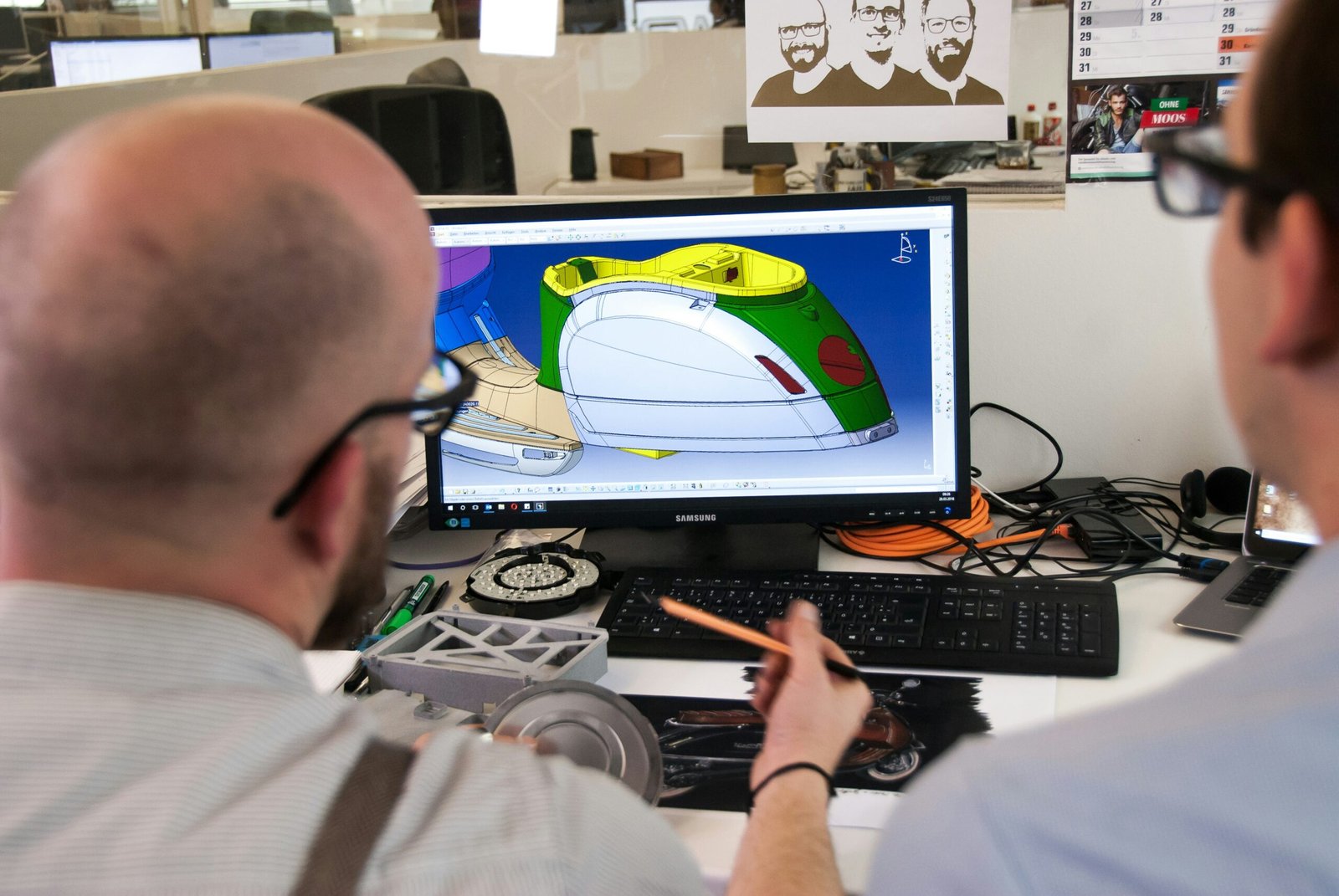

3D Scanning & Reverse Engineering

Turn physical parts into precise digital models. Whether you’re digitizing or reverse engineering your parts, we help you capture clean, usable data every time.

our 3D scanning capabilities

We use professional-grade blue and white-light 3D scanners to capture physical parts and convert them into detailed CAD files, ready for modification, duplication, or production. Our scanning services are ideal for:

Digitizing

Reverse Engineering

Is 3D scanning right for you?

3D scanning offers plenty of benefits in an advanced manufacturing workflow. It lets you capture real-world parts with precision and speed.

Whether you’re restoring legacy components, updating a hand-built prototype, or reverse engineering a complex form, scanning saves time and preserves critical details.

Use it to:

- Convert physical objects into editable CAD files

- Accelerate design modifications and validation

- Document production parts for archiving or reproduction

📂 File Outputs We Provide

We can deliver scan data in a variety of formats depending on your needs - whether you’re headed into CAD, simulation, 3D printing, or CNC.

Common File Formats:

- • STL (for 3D printing or inspection)

• OBJ (for textured mesh models)

• STEP or IGES (for CAD-ready surfaces via reverse engineering)

• Point cloud formats (e.g. .PLY, .E57)

🛠️ Post-Processing & Reverse Engineering

Want more than raw scan data? We’ve got you covered.

We offer full reverse engineering services to convert your scan into editable 3D models ready for prototyping or production.

This includes:

-

• Mesh clean-up and hole filling

• Surface reconstruction and solid modeling

• Feature extraction and parametric CAD modeling

• Model comparison and inspection reports

Ready to Get Started?

We work with soloprenaurs, startups, or product teams ready to move fast and build smarter.