3D Printing Services

From prototypes to production-ready parts, we fabricate your projects with care and confidence. Turnarounds as fast as same-day.

our 3D printing capabilities

FDM Printing

SLA Printing

Ready to have Parts printed? Get An Instant Quote Now.

FDM Printing

Why choose FDM?

Fused Deposition Modeling (FDM) is a go-to process for fast, cost-effective 3D printing. It's ideal for everything from early prototypes to functional, end-use parts. It works by extruding thermoplastic filament layer by layer, offering design flexibility, material variety, and scalability.

Common applications include design and functional prototypes, jigs and fixtures, custom tooling, and large display pieces for marketing activations.

Printer Capacity

We use over 15 different desktop and industrial large-format FDM 3D printers, ensuring we have capacity for batch production and same-day turnarounds.

3D Printers We Use

- Bambu Labs: A1, P1S, X1E, H2D

- BigRep: VIIO 250

Materials We Offer

We offer a wide selection of materials to ensure you have the best product possible for your application.

Current Materials

- Standard: PLA, PETG, PCTG, ASA, ABS

- Engineering: PA6/66, TPU 95A,

- Filled Materials: PETG-CF, PA12 CF, ABS-GF, PP-GF30

Post-Processing

Want to take your prints even further? We offer post-processing services to bring your full idea to life, including:

- Sanding and painting

- Embedding electronics (lights, PCB boards, etc.)

- Custom wrapping (leather, alcantara)

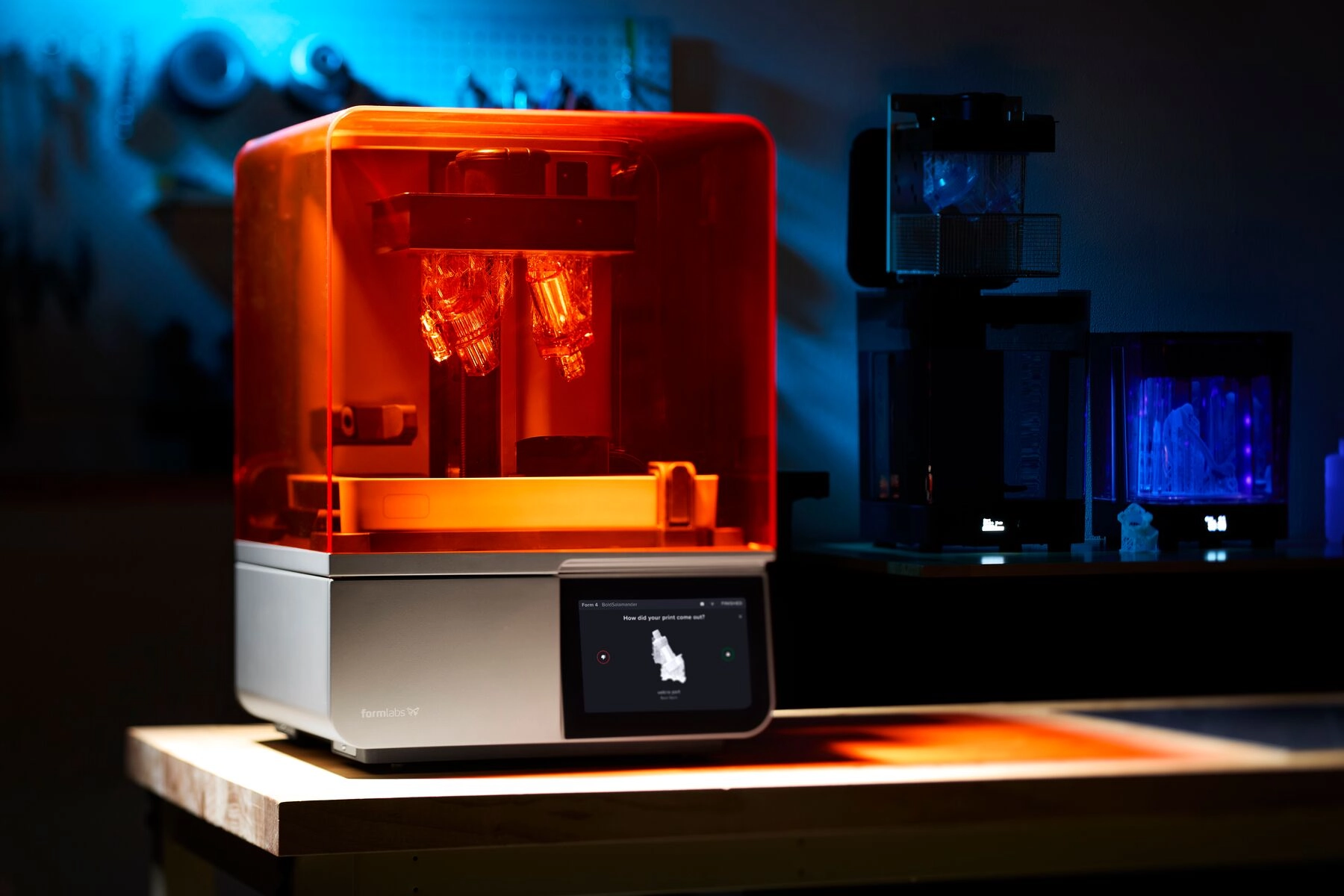

SLA Printing

Why choose SLA?

Stereolithography (SLA) is known for its incredibly smooth surface finish and high-resolution detail, making it the top choice when aesthetics, tight tolerances, or mold-like quality is key.

SLA is ideal for product designers who need showroom-ready prototypes, engineers validating precise geometry, or anyone producing intricate, small-scale parts. It’s also the closest you’ll get to injection molding quality without the tooling.

Printer Capacity

Our six resin printers stay productive. Each uses a variation on DLP technology with the finest resolution, ensuring your parts come out smooth and presentable.

Resin Printers We Use

- Formlabs: Form 4, Form 4L

- ANYCUBIC: Photon Mono M7 PRO

Materials We Offer

We offer a wide selection of materials to ensure you have the best product possible for your application.

Current Materials

- Standard (ABS-Like): Grey, Clear, White, Black

- Engineering: Tough 1500, Durable

Post-Processing

Want to take your prints even further? We offer post-processing services to bring your full idea to life, including:

- Sanding and painting

- Embedding electronics (lights, PCB boards, etc.)

- Custom wrapping (leather, alcantara)

Why Print with AmplifyAM?

What Sets Us Apart

Fast Turnaround

Fast is our default operation. Most parts ship in a few business days after project kickoff.

Local Support

No phone trees, no complex org structure. We're ready to work with you.

Hands-On Service

From file prep to material selection, we guide you through every step with care.

Flexible

Need design help? Switching materials mid-project? We’re built to adapt with you.

Satisfaction Guarantee

We stand behind our work. If a part doesn’t meet expectations, we’ll make it right.

Collaboration

We’re not just printing parts; we’re helping you bring your idea to life.

Ready to Get Started?

We’ve helped founders, engineers, and product teams bring ideas to life with local, on-demand manufacturing.

Ready to build something great with us?